Understanding Air Hoses and Fittings

What Are Air Hoses and Fittings?

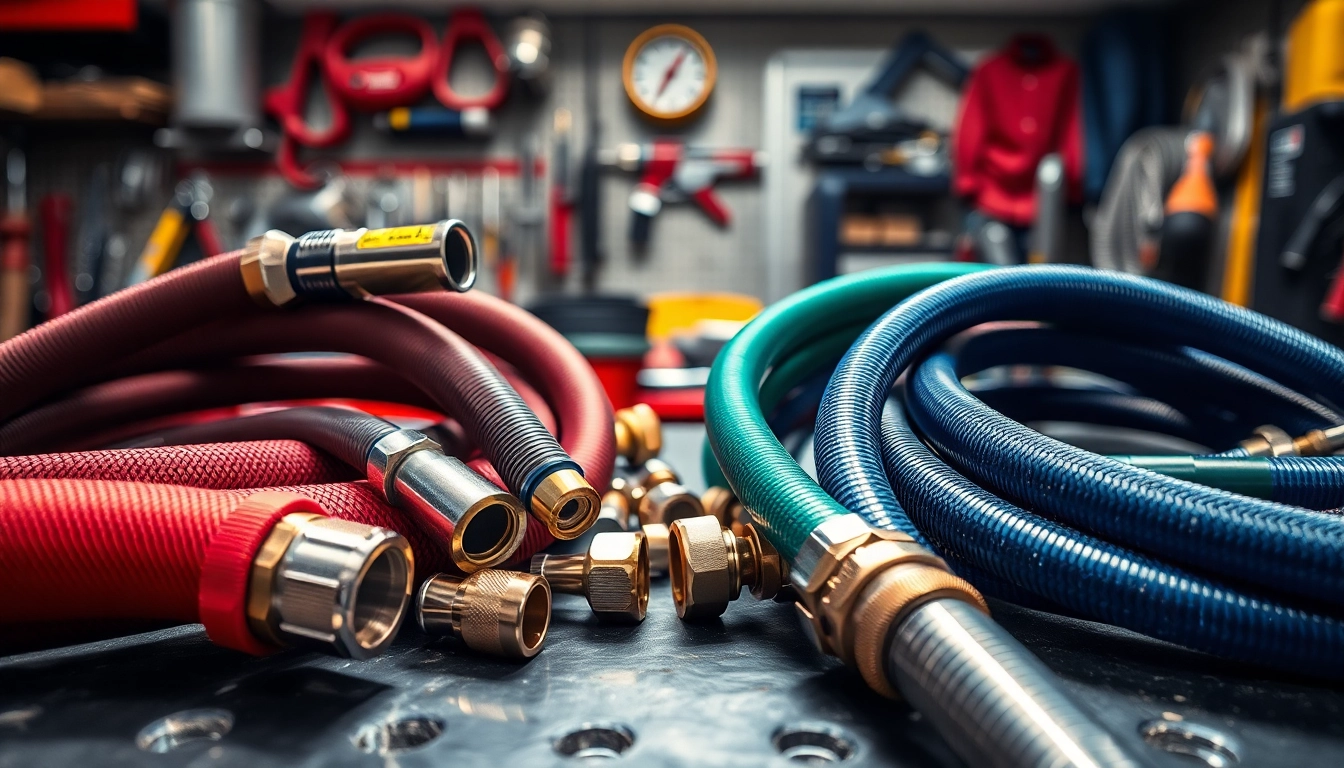

Air hoses and fittings are essential components in pneumatic systems, serving as the flexible conduit for compressed air used in various applications, from powering air tools to operating industrial machinery. An air hose is essentially a durable tube designed to transport compressed air from a compressor to a tool or another location where air is needed. The fittings, on the other hand, are connectors that link hoses to tools or compressor outlets, ensuring a secure and leak-free connection. These components are vital in maintaining consistent airflow and pressure, contributing to the efficiency and effectiveness of pneumatic systems.

Common Applications for Air Hoses

Air hoses are employed across diverse industries including automotive, construction, manufacturing, and home improvement. Within these sectors, applications can include:

- Powering Pneumatic Tools: Air hoses supply compressed air to tools such as nail guns, impact wrenches, and spray paint guns, facilitating work that requires high power.

- Cleaning and Inflation: Air hoses are commonly used for blowing dust off machinery or inflating tires and sports equipment.

- Manufacturing Processes: In industrial settings, air hoses connect equipment like air cylinders and pneumatic actuators to compress air for operations.

- HVAC Systems: They are also vital in HVAC systems for controlling air pressure and temperature.

Types of Air Hose Fittings Explained

Air hose fittings come in various sizes, types, and materials to accommodate different applications and ensure compatibility with various air hoses and tools. Some common types include:

- Quick Connect Fittings: Allow for fast and easy connection and disconnection of hoses and tools without the need for wrenches.

- NPT (National Pipe Thread) Fittings: These tapered fittings create a secure seal when connected to corresponding threads.

- Barb Fittings: Typically used with flexible hoses, barb fittings have ridges that hold the hose securely in place.

- Swivel Fittings: These fittings allow for 360-degree rotation, reducing hose twisting and kinking during operation.

Choosing the Right Air Hose

Factors to Consider When Selecting Air Hoses

When selecting air hoses, several factors must be considered to ensure the hose meets the demands of your application:

- Pressure Rating: Consider the maximum pressure that the hose will be subjected to during use. Hoses should be rated for those pressures to prevent ruptures.

- Temperature Range: Ensure the hose can withstand the temperature extremes it may encounter, from freezing cold to scorching heat.

- Flexibility and Durability: Depending on your application, you may need a hose that is highly flexible or one that can withstand rough handling and abrasion.

- Length and Diameter: Choose a hose length that suits your setup and a diameter that ensures sufficient airflow without excessive pressure drop.

Material Comparisons: Rubber vs. PVC

The material of an air hose significantly affects its performance and longevity. The two most common materials are rubber and PVC:

- Rubber: Rubber hoses are highly flexible and can withstand extreme temperatures and weather conditions. They are resistant to abrasion and kinking, making them ideal for demanding environments.

- PVC: PVC hoses are lighter and often less expensive than rubber options. They are less flexible, especially in cold temperatures, but are very durable and can handle moderate pressure applications.

Understanding Hose Length and Diameter

The length and diameter of your air hose impact both performance and convenience:

- Length: Longer hoses allow for more range in your workspace, but can reduce airflow and lead to higher pressure drops. Shorter hoses typically maintain pressure better but may limit movement.

- Diameter: The diameter of the hose affects the flow rate. A larger diameter allows for more airflow but is bulkier, whereas a smaller diameter can restrict flow, so it is essential to match the hose diameter with the tool requirements.

Essential Accessories for Air Hoses

Types of Couplings and Connectors

Air hose couplings and connectors are crucial for creating secure and effective connections within pneumatic systems. Options include:

- Push-to-Connect: These connectors allow for quick and easy connections without threading.

- Threaded Connectors: Commonly used in industrial applications, these provide a more permanent connection.

- Barbed Connectors: Used with flexible hoses, these fittings use friction to secure the hose to the connector for leak-free performance.

- Safety Couplers: These couplers include mechanisms or features designed to prevent accidental disconnections during operation.

Hose Reels and Storage Solutions

Proper storage of air hoses not only prolongs their lifespan but also keeps your workspace organized. Hose reels can be an excellent solution for managing longer hoses. They allow for:

- Easy Storage: Keeps hoses neatly coiled when not in use, preventing kinks and tangles.

- Convenient Access: Most reels can be mounted on walls or kept mobile for easy access as needed.

- Prolonged Hose Life: Reduces wear and tear by preventing hoses from sitting on hard surfaces or becoming tangled.

Thread Sealants and Maintenance Products

Maintaining air hoses and fittings is critical for ensuring their longevity and performance. Thread sealants can prevent leaks in threaded connections. It is advisable to select products made specifically for pneumatic systems to ensure compatibility and effectiveness. Regular inspection of hose fittings for wear or damage can prevent more significant issues down the line, and replacing any worn parts can save on costly repairs.

Installation and Usage Tips

How to Properly Connect Air Hoses and Fittings

Proper connection of air hoses and fittings is vital in preventing air leaks and ensuring efficient operation:

- Clean both the hose and fitting to ensure proper sealing.

- For threaded fittings, apply a suitable thread sealant before connecting.

- Tighten the connection securely, being cautious not to over-tighten, which may damage the threads.

- Test for leaks before using the hose extensively, using soap and water or a leak detection solution.

Best Practices for Ensuring Longevity

To ensure your air hoses and fittings last, follow these best practices:

- Store hoses properly, preventing exposure to UV rays or extreme temperatures.

- Inspect hoses regularly for damage or wear, replacing components as necessary.

- Use hose reels when storing to prevent tangling and kinking.

- Maintain a suitable working pressure according to the hose specifications.

Avoiding Common Mistakes in Use

Many mistakes can lead to premature failure of air hoses and fittings; here are a few common errors to avoid:

- Over-tightening: This can damage fittings and lead to leaks.

- Using Mismatched Parts: Ensure that all parts are compatible in size and type to prevent leaks and performance issues.

- Neglecting to Secure Connections: Loose connections can lead to air leaks and inefficient tool operation.

Where to Buy Quality Air Hoses and Fittings

Top Online Retailers for Air Tool Accessories

When looking to purchase air hoses and fittings, various online retailers offer a wide selection. Some popular choices include reputable sites like air hoses and fittings, Steelman Tools, and JACO, providing options for every budget and application.

Local Hardware Stores vs. Online Options

While buying locally allows for immediate access and the ability to inspect products firsthand, online purchasing offers extensive options, often at competitive prices. Additionally, online platforms frequently provide user reviews, which can be valuable in making an informed decision.

Identifying Trusted Brands and Products

When selecting air hoses and fittings, it’s crucial to choose reputable brands known for quality and durability. Look for manufacturers with solid warranties and good customer feedback. Factors to consider include:

- Reputation within the industry

- Customer reviews and ratings

- Availability of replacement parts and customer support